Your cart is currently empty!

Dobinsons 1.75″-2.5″ Lift Kit for Toyota Land Cruiser LJ78 LJ79 RJ77 KZJ78 1987-96 Square Headlights

- For 1987-1996 Toyota 70 Series 5-door models, LJ78, LJ79, RJ77, KZJ78 with Square Headlights and 2.4L petrol or 2.4L diesel engines

- Complete suspension kit for 4×4 Off Road Use, fine tuned to match the vehicle

- Coils are specifically suited to match OE fitment specs

- Nitrogen Gas Charged Shocks, Superior Design, thicker walls, longer travel

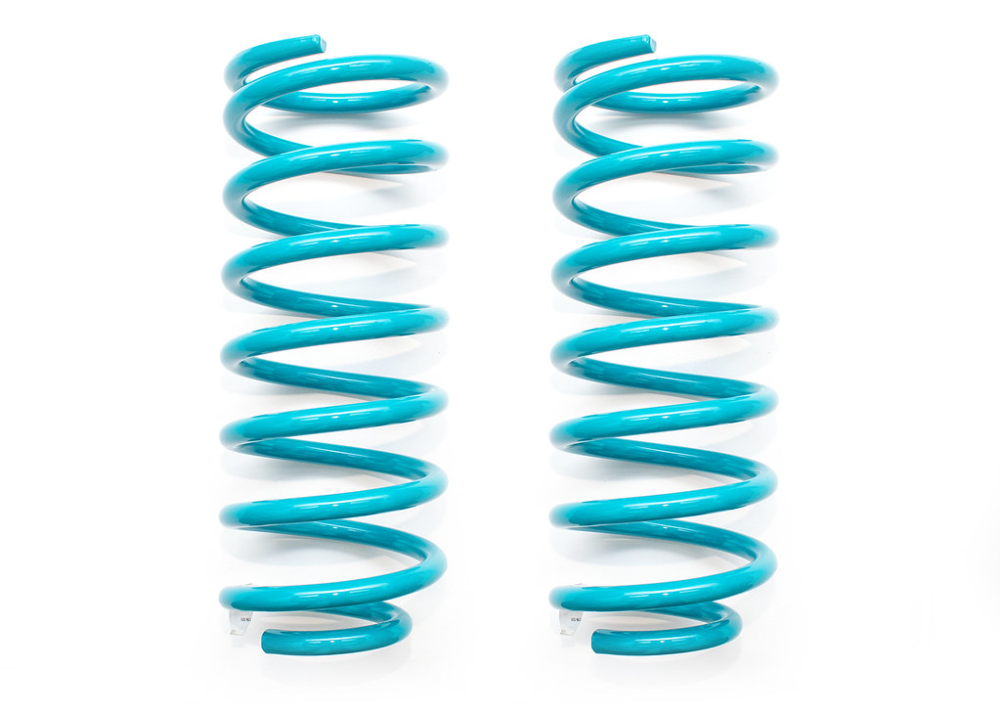

- High Quality Australian-made coil springs, heat treated, fully scragged, powder coated

- Base kit includes front and rear coils and shocks, choose optional parts below

- Choose your coils and load carrying ability, anywhere from 1.75″ up to 2.5″ of Lift

From $1,160.00

In StockC59-244 - 2.5" with up to 110LBS

GS59-634 - Long Travel Twin tube nitrogas shocks for 2.5" Lifts only

IMS59-60634 - Long Travel Monotube IFP shocks for 2.5" Lifts only

C59-247 - 2.5" with up to 220LBS constant load - required weight

GS59-633 - Long Travel Twin Tube nitrogas shocks for 2.5" lifts only

IMS59-60633 - Long Travel Monotube IFP Shocks for 2.5" Lifts only

Description

Dobinsons offer this complete suspension system for the 1987 to 1996 model Toyota Land Cruiser 70 Series Station Wagon (5-door models), including models LJ78, LJ79, RJ77, KZJ78 – with Square headlights, with different coil and height options offered in the drop down boxes. Using the amount of adding weight/load to your vehicle, such as bumpers, winch, 2nd battery, etc, choose the appropriate weight coil and desired lift height.

These vehicles can also be called 70 Series Prado I, or Landcruiser II or Land Cruiser II. They all have coil springs front and rear and square headlights and 2.4L petrol or 2.4L diesel engines. These are the 5-door station wagon models, not to be confused with the short wheelbase models.

This Kit includes front and rear shocks and coils. Additional parts available to add on.

Caster bushing kit is not included, but is strongly recommended for 1.75″+ lifts so that the correct front end caster is achieved, resulting in a proper wheel alignment and the best ride quality. Not correcting the caster will not have the vehicle driving as ideally as possible.

***Contact us directly for info about the coils for different load options or questions***

Designed, developed and tested in Australia by Dobinsons Spring & Suspension, in-house suspension design engineers, Dobinsons 4×4 shock absorbers and coil springs are designed and tested to perform in the harshest conditions right across the world. We export to over 40 countries worldwide from our Australian head office, the importance of quality is at the forefront in the complete design and manufacturing process. This ensures every shock and coil spring can withstand the blistering heat and corrugations of the Australian outback right through to the subzero temperatures of a Russian winter.

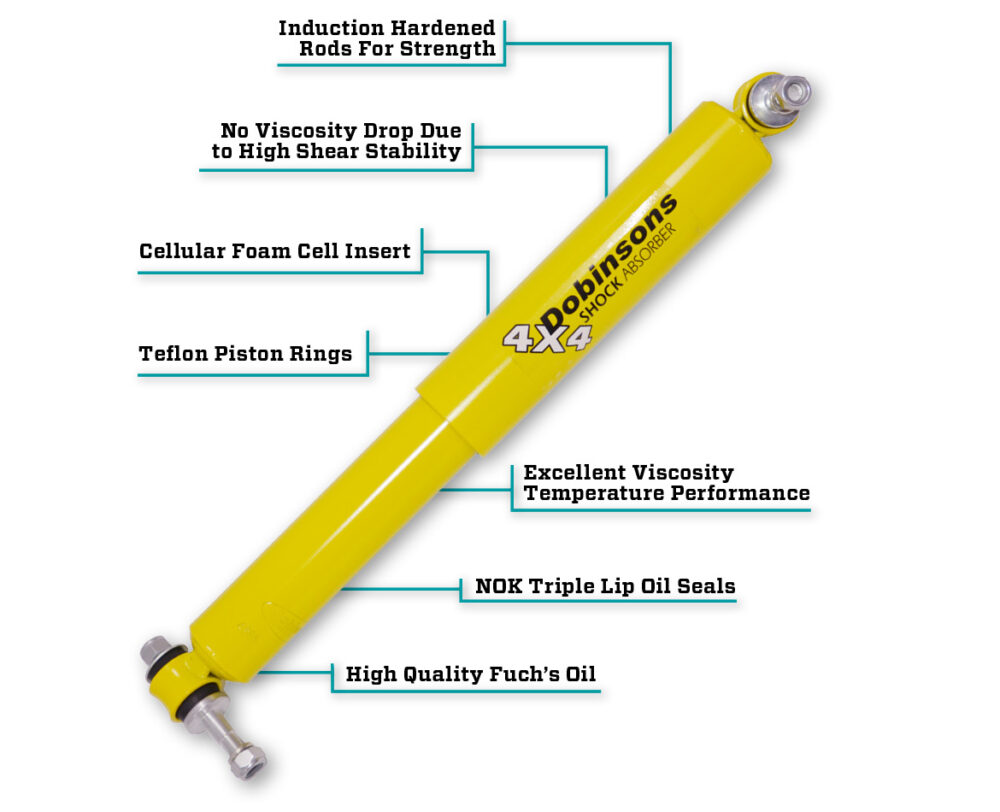

Our Twin Tube Nitrogen Gas charged shock absorbers are made from the world’s highest quality external and internal parts sourced worldwide. They provide a significant increase in performance over the standard shock absorbers. Our twin tube shock absorbers feature larger bodies, larger bores and increased valving performance to dramatically improve vehicle handling and control and reduces shock fade.

We proudly manufacture the highest quality replacement coil springs for many different applications, complying to ISO9001:2008 international quality standards from our state of the art manufacturing facility in Central Queensland, Australia.

All our coil springs are load tested and scragged 100% to eliminate subsequent spring sag. We also perform spring fatigue and hardness testing using in-house state of the art testing equipment.