Your cart is currently empty!

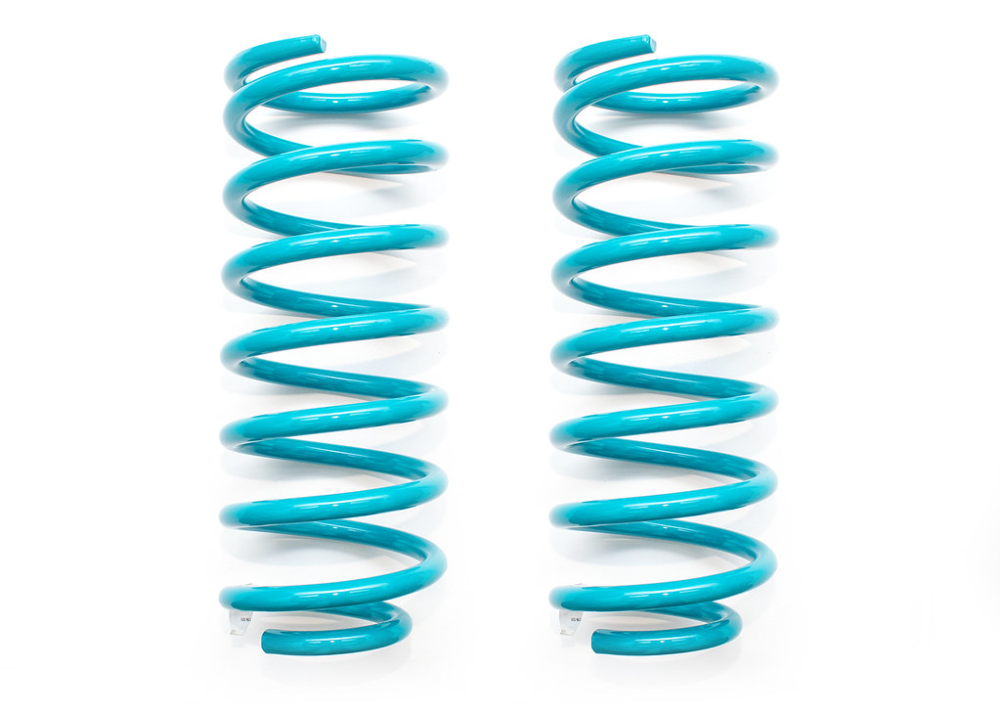

A durable powdercoat finish provides extreme protection against the elements.

To see all coil spring options from Dobinsons, click this link: https://exitoffroad.com/product-category/suspension/coil-springs/

Vehicle Fitment:

2003 Toyota 4Runner

2004 Toyota 4Runner

2005 Toyota 4Runner

2006 Toyota 4Runner

2007 Toyota 4Runner

2008 Toyota 4Runner

2009 Toyota 4Runner

2010 Toyota 4Runner

2011 Toyota 4Runner

2012 Toyota 4Runner

2013 Toyota 4Runner

2014 Toyota 4Runner

2015 Toyota 4Runner

2016 Toyota 4Runner

2017 Toyota 4Runner

2018 Toyota 4Runner

2019 Toyota 4Runner

2020 Toyota 4Runner

2021 Toyota 4Runner

2022 Toyota 4Runner

2023 Toyota 4Runner

2024 Toyota 4Runner

2003 Lexus GX470

2004 Lexus GX470

2005 Lexus GX470

2006 Lexus GX470

2007 Lexus GX470

2008 Lexus GX470

2009 Lexus GX470

2010 Lexus GX460

2011 Lexus GX460

2012 Lexus GX460

2013 Lexus GX460

2014 Lexus GX460

2015 Lexus GX460

2016 Lexus GX460

2017 Lexus GX460

2018 Lexus GX460

2019 Lexus GX460

2020 Lexus GX460

2021 Lexus GX460

2022 Lexus GX460

2023 Lexus GX460

2006 Toyota FJ Cruiser

2007 Toyota FJ Cruiser

2008 Toyota FJ Cruiser

2009 Toyota FJ Cruiser

2010 Toyota FJ Cruiser

2011 Toyota FJ Cruiser

2012 Toyota FJ Cruiser

2013 Toyota FJ Cruiser

2014 Toyota FJ Cruiser

2015 Toyota FJ Cruiser

2016 Toyota FJ Cruiser

2005 Toyota Tacoma

2006 Toyota Tacoma

2007 Toyota Tacoma

2008 Toyota Tacoma

2009 Toyota Tacoma

2010 Toyota Tacoma

2011 Toyota Tacoma

2012 Toyota Tacoma

2013 Toyota Tacoma

2014 Toyota Tacoma

2015 Toyota Tacoma

2016 Toyota Tacoma

2017 Toyota Tacoma

2018 Toyota Tacoma

2019 Toyota Tacoma

2020 Toyota Tacoma

2021 Toyota Tacoma

2022 Toyota Tacoma

2023 Toyota Tacoma

Daniel (verified owner) –

Very fast delivery.

Scott (verified owner) –

I received it really fast.

Travis (verified owner) –

Spoke with Mike, he got me headed in the right direction for what I need.

Joshua (verified owner) –

Spoke with Mike, he got me headed in the right direction for what I need.

Patrick (verified owner) –

Exit Offroad really does know what they’re talking about, they have the best product pages.

James (verified owner) –

Very good customer service, super friendly.

Andrew (verified owner) –

5 Stars!!

Bradley (verified owner) –

Just what I needed.

Eric (verified owner) –

Very good customer service, super friendly.