Your cart is currently empty!

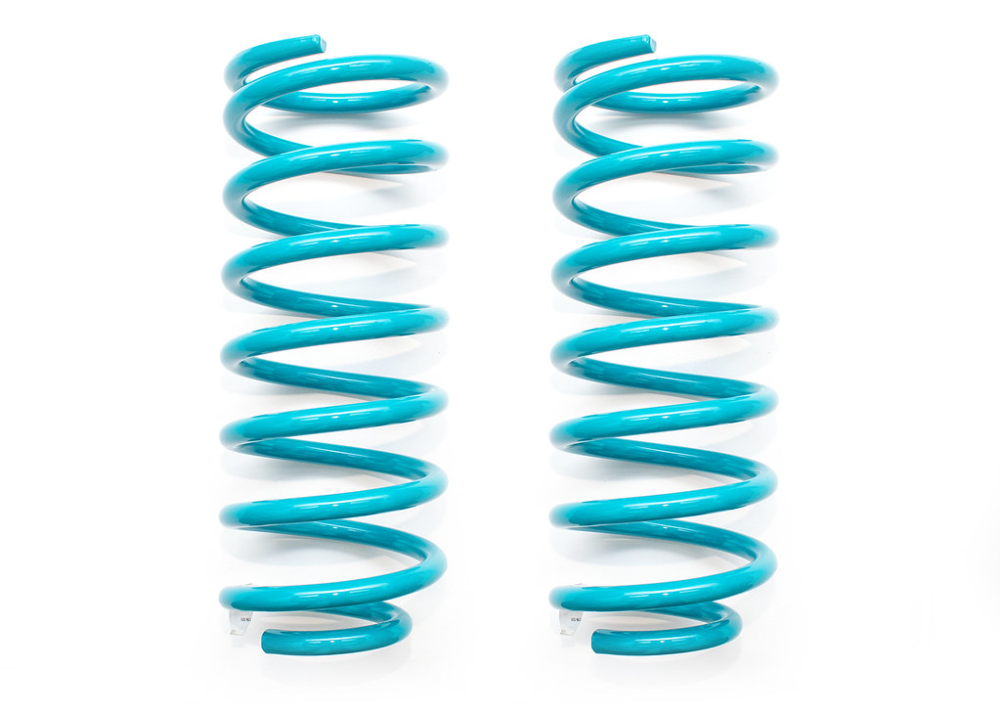

Dobinsons Rear Coil Spring Options | Toyota Sequoia 2023+

- Suits Toyota Sequoia 2023+, choose the appropriate lift height that also matches any added weight you’ve put on the car

- Fully Designed, Manufactured, and Finished In Australia

- Ultra modern design technology, Fully Scragged & Load Tested

- State of the Art Heat Treatment, High Intensity Shot Peened

- Formed on Precision Mandrels, Precise End Configurations

- Durable Powder Coat Finish

- Coils are Sold in Pairs

- Lifting the rear 2″ requires a new Panhard Rod to re-center the axle

- Lifting 1″ or more, new rear sway bar links are necessary

- 2″ of rear lift also requires longer shocks than stock

From $270.00

In StockTRD Pro models yield 1" less lift than listed below, since they come lifted already from the factory

C59-817V - Stock height with stock weight

C59-819V - 1" Lift with stock weight

C59-821V - 2" Lift with stock weight, 1" Lift with 220-440lbs added weight

C59-823V - 2" Lift with 220-440lbs added weight

C59-851V - TRD PRO ONLY 2" Lift with stock weight

C59-853V - TRD PRO ONLY 2" Lift with 440lbs constant weight

Description

Sequoia Rear Springs from Dobinsons Spring & Suspension™ proudly manufacture the highest quality replacement coil springs for many different applications, complying to ISO9001:2008 international quality standards from their state of the art manufacturing facility in Central Queensland, Australia.

We proudly boast one of the worlds largest range of Sequoia rear springs, including raised height and heavy duty 4WD springs, lowered performance passenger car springs, O.E. replacement springs and heavy duty springs for commercial vehicles.

All our 2023 Sequoia lift coil springs are load tested and scragged 100% to eliminate subsequent spring sag, and ensure they meet and maintain the required specifications. We also perform spring fatigue and hardness testing using in-house state of the art testing equipment.

Our design engineers utilize the latest coil spring design programs to ensure each spring meets or exceeds the design requirements, to achieve maximum working life. These state-of-the-art design programs are crucial when designing variable/progressive rate springs, ensuring laden and unladen spring rates are correct, providing the best possible ride comfort and handling.